2025 is a year defined by volatility—and opportunity.

Rising tariffs, unpredictable trade policy, and global supply chain fragmentation have created immense pressure on businesses. Many are reacting the only way they know how: cutting costs, delaying investments, reducing headcount. But the truth is: cost-cutting can only buy you so much time.

What it doesn’t buy is a future.

At Ziba, we’ve spent over four decades helping companies navigate inflection points like this—not just to survive them, but to grow stronger because of them. What’s clear now is that we are not in a temporary disruption. We are in a systemic shift.

And that shift demands a new playbook.

Onshoring Isn’t a Trend. It’s a Structural Reality.

Offshoring made economic sense for decades. Manufacturing in China, Vietnam, or Mexico meant access to low labor costs and infinite scalability. Supply chains were invisible, at least until they weren’t. The U.S. alone accounts for $62 billion of the $92.5 billion global outsourcing industry.

But that logic is cracking.

Trade wars, COVID-era shortages, geopolitical risks, rising wages abroad (Chinese manufacturing wages have increased over 400% since 2000), and growing environmental accountability have converged to make offshore production not just risky—but in many cases, inefficient and unsustainable. Onshoring isn’t a “maybe someday” concept. It’s a necessity—and it’s already happening.

Major players are investing at scale: Eli Lilly has invested over $50B in U.S. facilities since 2020. Nvidia plans to invest $500B in U.S.-based AI infrastructure over the next four years. In total, over $800 billion has been committed to US manufacturing over the last few years, with a 26% increase in manufacturing construction in January 2024.

But here’s the often-overlooked reality: you can’t simply relocate existing products to U.S. soil and expect them to work.

American manufacturing operates differently. It leans on automation, precision, modularity, and a deeply skilled (but undersized) workforce. It thrives not on volume, but on adaptability. That means designing for capability—not just for cost.

From Labor Arbitrage to Design Advantage

Offshore manufacturing allowed for design excess. Almost any product idea could be brought to life with enough labor. Designers responded to marketing requests to “make it different” with more features, more complexity, more variation—because they could still be produced affordably, thanks to low labor costs.

We reviewed countless product concepts in the 2000s—many of them different for the sake of difference, often impractical unless labor was $1/hour. These weren’t products engineered for excellence. They were engineered to exploit offshore economics.

Today, that kind of thinking—along with the design and engineering practices that come with it—can break your business.

Design must once again return to its roots: clarity, simplicity, intelligence, precision and, purpose. We must eliminate the unnecessary, elevate the meaningful, and ensure that every product can be built reliably and economically—within the capabilities of domestic production systems which are build on:

Automation, not manual assembly

Precision and modularity, not excess

A skilled but limited workforce (only 8% of Americans work in manufacturing today vs. 25% in 1970)

Onshoring success hinges on designing for capability—not just for cost.

What the iPod Got Right (and Why It Still Matters)

Apple didn’t sell the iPod with specs. It sold it with a story: "1,000 songs in your pocket."No mention of features. Just a simple story of meaningful benefit.

In an era where consumers are flooded with options and exhausted by complexity, that clarity matters more than ever. As production shifts closer to home, companies have a rare opportunity to redesign not just how products are made—but why they exist. Simplicity, purpose, and emotional resonance aren’t trade-offs. They’re competitive advantages.

Experience-rich beats feature-rich. Always has. Always will.

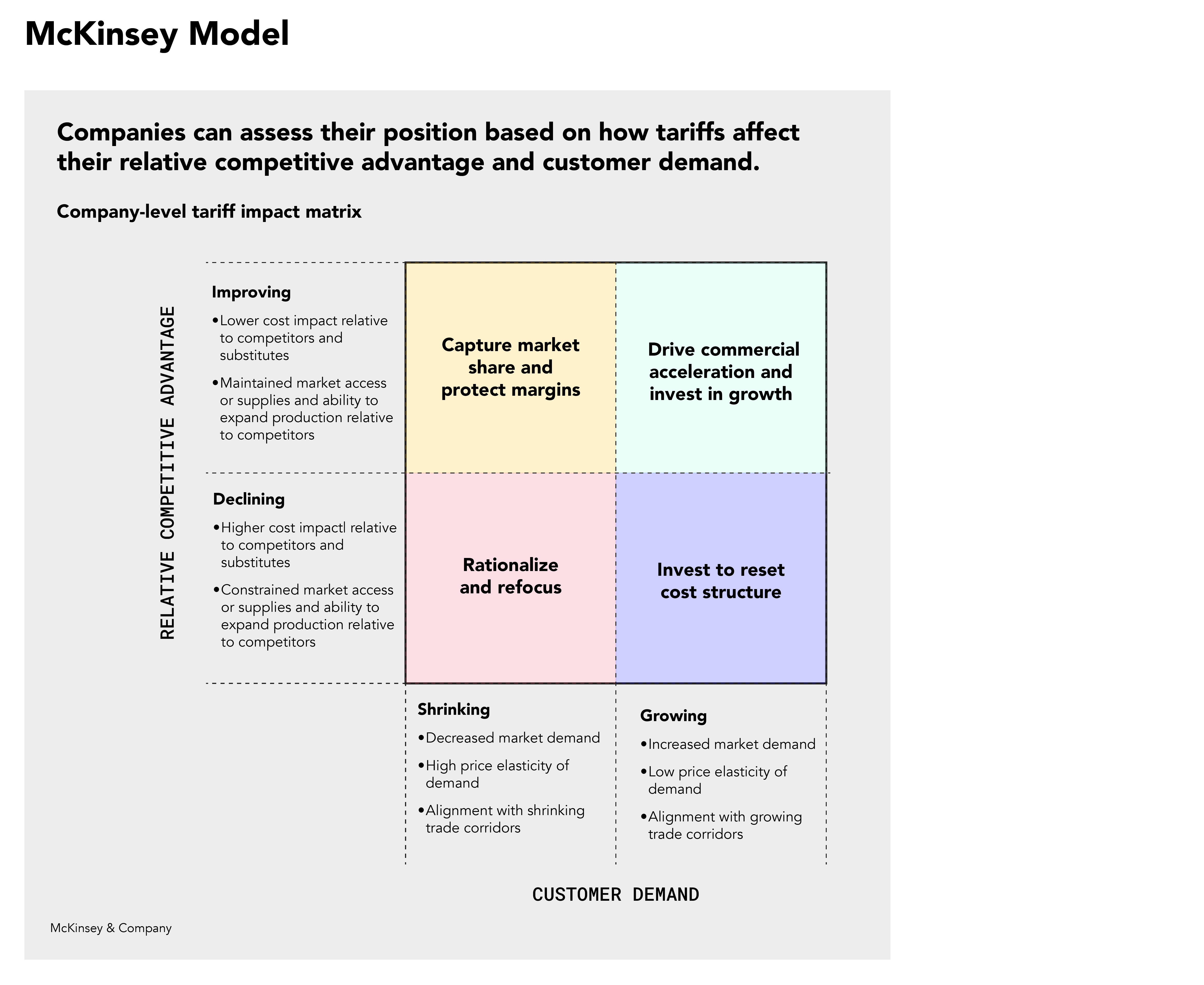

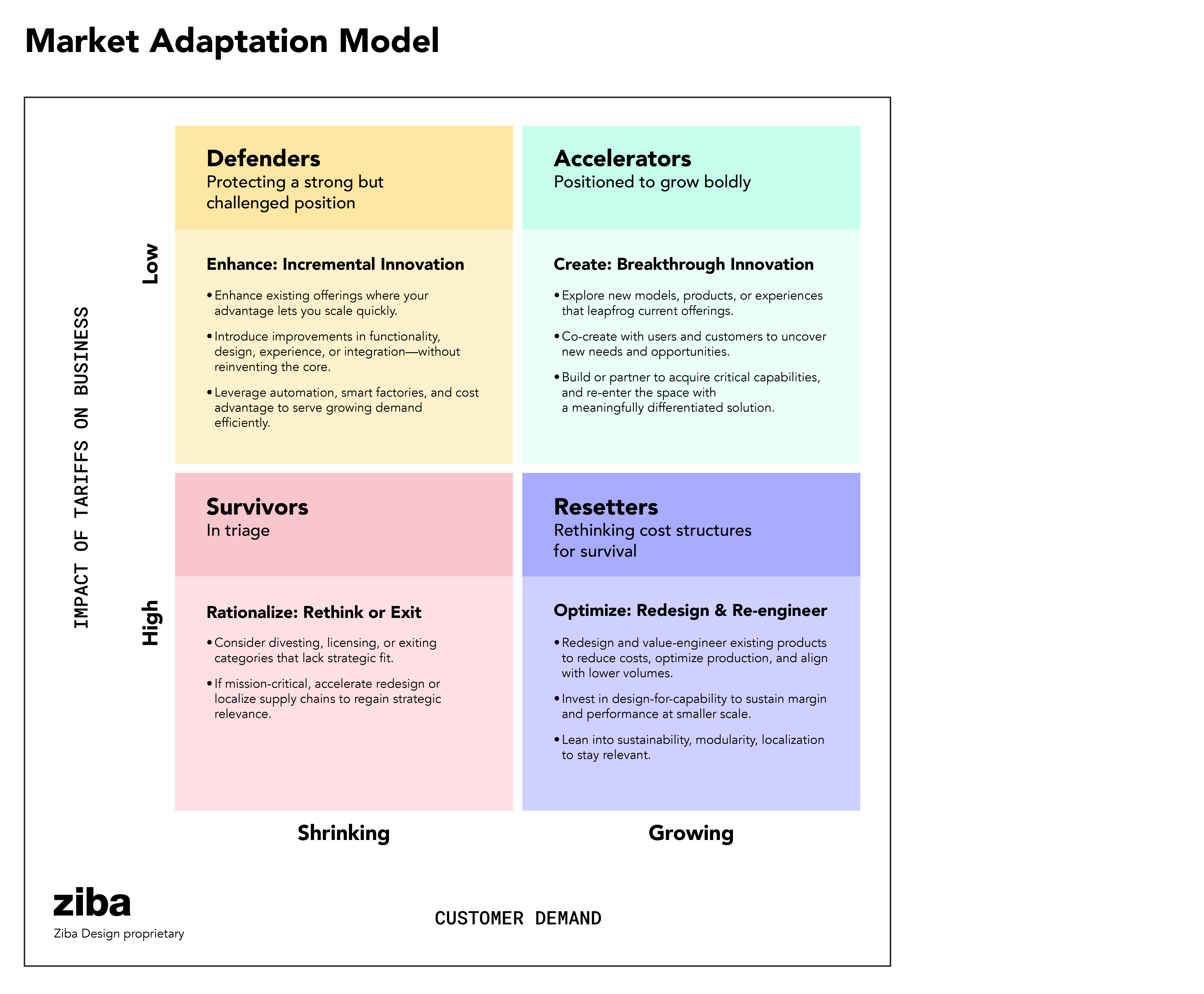

The McKinsey Framework—and How Design Fits In

Recently, McKinsey released a report outlining four strategic postures companies can adopt in the face of global trade disruption. What struck us was how naturally these postures map to how Ziba has supported its clients over the years.

When we helped launch the USB flash drive or the Clorox ReadyMop, the market wasn’t asking for them—those categories didn’t exist yet. But the insight was clear, and the need was real. That’s an Accelerator move: don’t wait for the future—build it.

With Umpqua Bank and Coleman, the strategy was different. We weren’t adding—we were subtracting. Simplifying the experience. Streamlining the product. Making it intuitive and emotionally resonant. That’s what Defenders do: protect their position by focusing on what matters most.

And when Heinz needed to rethink their ketchup bottles, we reduced SKUs, standardized parts, and kept what made the brand iconic. A Resetter move: cut complexity, keep identity.

Wherever you are—leading, defending, or rebuilding—design can support your path forward. But only when it’s applied with strategic clarity—with a deep understanding of your posture, your market, your capabilities, and focused on value.

Designing for American Capabilities: A 4-Part Framework

Successful onshoring requires more than relocation—it demands smart, strategic redesign aligned with U.S. manufacturing realities. Here’s how the most forward-thinking companies are approaching it:

Designing for Automation

Simplifying production by reducing part counts, enabling robotic assembly, and integrating smart features like sensors and AI for real-time monitoring and optimization.

Embracing Modular Design

Building flexible platforms with shared components across product lines. This cuts complexity, streamlines inventory, and reduces tooling costs—by as much as 60%.

Integrating Digital Tools

Leveraging AI, simulation, and digital twins to accelerate prototyping, shorten time-to-market by up to 40%, and continuously improve performance with live data.

Prioritizing Sustainable Sourcing

Designing for the full lifecycle by choosing materials that meet Environmental, Social, and Governance (ESG) goals, comply with regulations like Extended Producer Responsibility (EPR), and support recycling, reuse, and circularity from the start.

It’s not about nostalgia for a time when everything was made in America. It’s about being smarter with what we can make here now.

What We Learned in the '80s—and Why It Still Matters

In the early days of Ziba, we collaborated with companies navigating increased competition from Japanese and German manufacturers. These products often stood out for their build quality, engineering precision, and often better design. For many U.S. companies, the challenge wasn’t just cost—it was staying relevant in a changing global market.

Our approach went beyond aesthetics. We focused on the core of the product—redesigning for faster assembly, fewer parts, reduced waste, and more intuitive function. It was about making design a strategic lever for restoring competitiveness.

Now, history rhymes.

The lesson is timeless: If you want to lead, you can’t keep building yesterday’s products with tomorrow’s tools. You have to rethink what you make, how you make it, and why it matters.

From Restraint to Reinvention

These days, we often hear from executives who are hesitating—delaying decisions, cutting back to “weather the storm,” and waiting for stability before acting.

We understand the impulse. But we’ve seen what happens next: when demand returns, the companies that paused are outpaced by those who used disruption to rethink, retool, and reengineer.

Innovation doesn’t always mean disruption. Sometimes, it means streamlining what’s already working, realigning product lines with domestic capabilities, and ensuring that your offering isn’t just shippable—but meaningful.

Lead the Shift. Don’t Chase It.

We’re entering a moment of alignment between pressure and possibility:

Tariffs and labor costs are reshaping supply chains

Automation and AI are maturing rapidly

Consumers are demanding simpler, more meaningful experiences

It is a moment of rare clarity in business.

The forces shaping the future—economic pressure, technological readiness, and shifting customer expectations—are coming into focus. The tools to respond—digital prototyping, advanced manufacturing, agile product teams—have never been more powerful. The expectations of consumers—simplicity, value, experience—have never been more consistent.

What’s missing is the willingness to act.

And for those who do, the upside is real. According to McKinsey, companies that integrate digital-first, capability-aligned design can reduce total costs by up to 30% and dramatically improve time-to-market.

But that only happens when innovation is aligned with strategy. When design is done with intention. And when leadership embraces the idea that doing nothing is the biggest risk of all.

A Final Thought—and an Open Invitation

If you’re a CMO aligning brand with product strategy, a CDO building resilience, or an engineering leader bridging cost and capability— this is a call to lead and we’re here to help. Not with theory, but with four decades of actionable insight.

Let’s talk. Reach out to us here.

Together, we can turn this disruption into your next strategic advantage.